Overview of the categories of BERGER multispindle drillheads

We offer a wide variety of multispindle drillheads. All BERGER multispindle drillheads will offer you high use value.The Advantages of BERGER multispindle drillheads: simultaneous drilling of two or more holes in one operation

(drilling, countersinking, thread cutting or reaming, …)

Extensive Significant reduction of in machining time

(reduction of unit costs, increase in production capacity, reduction of in production time)

Depending on the application, we offer five lines of drillheads.

The following provides an overview.

Contact person:

Multispindle technology: thomas.berger@bergertech.ch

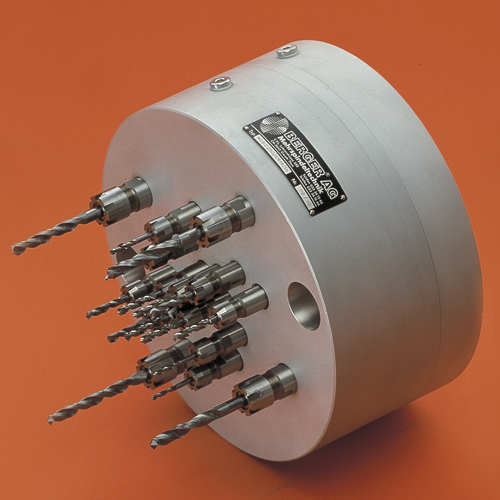

MSBZ-ER – versatile, rugged, exact

The classic among multispindle drillheads. The spindle-bearing system, with its honed-in needle bearing, is the noteworthy characteristic of the MSBZ. This creates a precise and extremely rugged bearing system which has produced optimal results in a great variety of applications. A wide range of spindle and housing designs are available to solve your machining issues.

MSBS – uncompromisingly high quality

MSBS drillheads are our top-quality product. The spindles are held by a set of three pre-loaded precision angular contact bearings. This special bearing-system offers a very rigid support and perfectly round rotation. This makes these multispindle drillheads well-suited for applications involving solid carbide tools. The gears are hardened and ground to reduce vibration to an absolute minimum.

MSBZ-EM – small, smaller, smallest

MSBZ-EM multispindle drillheads are our solution for machining tasks with a center-to-center distance between holes of less than 13 mm. The EM5 spindle, our smallest, can drill holes with a maximum diameter of 2 mm spaced a minimum of 7 mm apart. This spindle is entirely held by roller bearings as are all of our spindles.

MSBU– the reusable modular system

The idea behind the MSBU multispindle drillheads is unique. Assembled with only 5 different reusable components, the MSBU system offers you unsurpassed flexibility. The core of a MSBU multispindle drillhead is a rigid spindle plate.

MSBV– individually adjustable

The MSBV line of drillheads is equipped with continuously adjustable spindles and can thus be fitted to any required drill pattern. MSBV multispindle drillheads are also suitable for producing small lots since countless drill patterns can be obtained using a single drillhead. Thanks to the special spindle nose with 2 set screws (to secure the squared end of tap shafts), BERGER MSBV multispindle drillheads are suited to for both drilling and thread cutting.

MSBZ-ER – versatile, rugged, exact

The special characteristic of the MSBZ system is that spindles are mounted on individually non-floating, honed-in edged needle bearings and are thus suited to a diverse number variety of applications. The circular housing of the smallest MSBZ-ER drillhead produced to date has an outside diameter of just 70 mm. The largest MSBZ-ER drillhead with 22 spindles has a rectangular housing which measures 700 x 1200 mm.

Advantages of the MSBZ-ER line of drillheads

Very little downtime for you. MSBZ-ER drillheads are readily available and are tested high quality products.

Adapted to diverse customer needs thanks to a wide variety of spindles.

Suited for drilling, countersinking, reaming and thread cutting.

Application to high precision workpieces possible with optional drill-bushing plates.

Individual transmission ratio for each spindle thanks to the well thought-out design of the gear system (e.g. to achieve equal cutting speeds with tools of different diameters).

Application in restricted spaces thanks to the compact construction (e.g. lathe centers with driven tools).

Quick delivery thanks to the wide variety of spindles available and optimal warehousing.

A high level of service – ‘just-in-time’, including for spare parts.

Entirely produced in Switzerland by BERGER technologie GmbH.

Our products are manufactured of high-quality material using up-to-date machinery. Our workers are highly qualified and adhere to strict quality control standards.

Typical Areas of Application

Machining precision parts produced in large series are an ideal application for MSBZ-ER drillheads, e.g. finishing work on aluminum diecast parts (thread cutting).

Prospectus MSBZ PDF

General notes on adapters for BERGER multispindle drillheads can be found here.

MSBS – the uncompromising

Tools made of today's ultramodern materials such as solid-carbide, Cermet, or diamond demand ever better quality spindles in regard to stability, run-out and RPM. The MSBS line of drillheads satisfies these demands. The spindles are held with a set of 3 pre-loaded precision angular contact bearings. This special bearing-system gives a very rigid support to our spindles and guarantees a low TIR (total indicator run-out). HSK- or Komet-ABS spindle noses are available as well as weldon, whistle-notch or spindles with collet type nose (ER-collets). The gears are heat-treated and surface ground to allow high r.p.m. with very little vibration.

Typical Areas of Application

Precision parts produced in large series are an ideal application for MSBS drillheads, e.g. precise, bored holes or milling of datum-surfaces on aluminum diecast parts.

Advantages of the MSBS line of drillheads

Very little down time of your machinery since MSBS drillheads are a tested high quality product from BERGER technologie.

Adaptation to your needs is easy thanks to the wide variety of spindles.

Problem-free use with solid carbide tools thanks to very rigide spindle bearing-system with near perfect circular rotation.

Suitable for drilling, countersinking, reaming, thread cutting and milling.

Application to precision workpieces thanks to very rigide spindle bearing-system with near perfect circular rotation.

Application to high precision workpieces possible with optional drill-bushing plates.

Individual transmission ratio for each spindle thanks to the excellent design of the gear system (e.g. to achieve equal cutting speeds using tools with different diameters).

Applications in restricted spaces thanks to the compact construction (e.g. lathe centers with machine-driven tools).

Short delivery times thanks to the wide variety of spindles available and optimal stocks.

Excellent Customer Service – We deliver on time, including orders for spare parts.

Entirely produced in Switzerland by BERGER technologie GmbH.

Our products are manufactured of high-quality materials with modern machinery by qualified workers in keeping with high standards and systematic quality control.

MSBS – Highest quality, without compromise

General notes on adapters for BERGER multispindle drillheads can be found here.

MSBZ-EM – the small-sized spindles

The MSBZ-EM line of drillheads can be used, when the center distance between the individual boreholes is too small for the spindles of the MSBZ-ER line of drillheads. The MSBZ-EM drillheads are often equipped with a drill-bushing plate to additionally guide the small tools close to the workpiece. The small EM-spindles allow high r.p.m. for the small tool diameter due to the complete mounting on roller-bearings.

Advantages of the MSBZ-EM line of drillheads

Very little down time of your machinery since MSBZ-EM drillheads are a tested high quality product from BERGER technologie.

Adaptation to your needs is easy thanks to the wide variety of spindles.

Applications in extremely restricted spaces thanks to the compact construction (e.g. lathe centers with machine-driven tools). Suitable for drilling, countersinking, reaming and thread cutting.

Application to precision workpieces thanks to the rigid bearings of the spindles.

Application to high precision workpieces possible with optional drill-bushing plates.

General transmission ratio between point of entry and spindles is easily feasible. (protects the driving machines on applications needing high RPMs).

Individual transmission ratio for each spindle thanks to the excellent design of the gear system (e.g. to achieve equal cutting speeds using tools with different diameters).

Short delivery times thanks to the wide variety of spindles available and optimal stocks.

Excellent Customer Service – We deliver on time, including orders for spare parts.

Entirely produced in Switzerland by BERGER technologie GmbH.

Our products are manufactured of high-quality materials with modern machinery by qualified workers in keeping with high standards and systematic quality control.

Typical Areas of Application

Machining precision pieces produced in large series are an ideal application for MSBZ-EM drillheads, e.g. cylinders and housings of security locks.

MSBZ-EM – the smallest spindle possible!

General notes on adapters for BERGER multispindle drillheads can be found here.

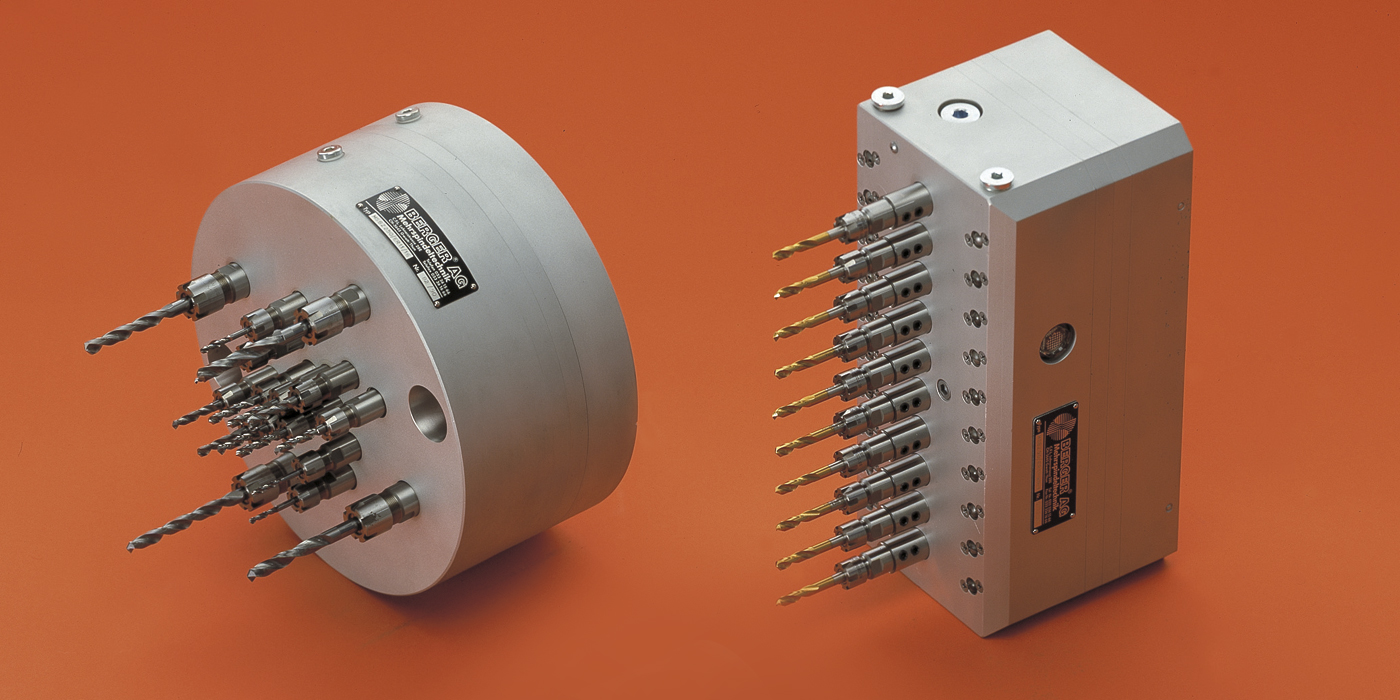

MSBU – the modular system

The idea behind the MSBU multispindle drillheads is unique. Assembled with only 5 different reusable components the MSBU system offers you a unsurpassed flexibility. The core of a MSBU multispindel drillhead is a rigid spindle plate. The drill-patteren is given by this jig bored spindle plate. The inividual spindle assemblies as well as the different gear assemblies are mounted to this spindel plate. This pre-assembled unit is then inserted and bolted into the housing. Only a new spindel plate is needed for a new drill pattern. All other components can be reused.

Advantages of the MSBU line of drillheads

The BERGER MSBU modular system achieves a low weight per spindle ratio due to its compact design. The drillhead accepts numerous hole patterns with this shallow housing design. Such as round, rec-tangular and in-line.

The jig bored spindle plate guaranties a high accuracy of the hole pattern. Once assembled, nothing can move or mis-adjust the hole pattern. This fact is important for your quality-control. All rotating parts are heat treated and surface ground. The gears are made from quenched and nitrate-hardened steel. The spindles are held by for roller-bearings.

Various tool chucking and quick change systems are available, like double angle, range type collets, whistle notch quick change chucks, straight shank holders, tapping chucks with tension and com-pression compensation.

The change over to different hole patterns can be done accurately in a few minutes. The oilbath lubri-cation makes the BERGER MSBU modular system virtually maintenance free.

For additional hole patterns only the spindle plate has to be made. Re-using the existing components saves up to 90% of the cost of a new multispindle drillhead. This gives you a fast ROI also in the production of small series.

MSBU – modular and reusable system

Prospectus MSBU to the Download on PDF

General notes on adapters for BERGER multispindle drillheads can be found here.

MSBV – the adjustable system

The unique feature of the MSBV line of multispindle drillheads is their possibility to adjust the center to center step less to fit your pattern. With the same Drillhead a whole variety of pattern can be machined, making them affordable also for smaller series of parts. BERGER MSBV multispindle drillheads can be used for drilling and tapping, two set-screws from the side hold the square end of the tap. Als Zubehör erhältliche Einstell-Schablonen (bereits nach Ihren Angaben bearbeitet oder als Rohlinge) vereinfachen und erleichtern die rasche Einrichtung neuer Bohrbilder.

MSBV – self adjustable, delivery from stock

MSBV construction

BERGER MSBV sets the new quality standard for adjustable multispindle drillheads: The rigid bearingsystem is based on roller-bearings only, with each spindle honed in to provide a support with no play at all. MSBV drillheads are made of specially selected high-quality materials. The spindles and shafts are hardened an ground/polished. The gears are made of quenched steel and nitrate-hardened. The BERGER MSBV quality is one of its kind!

The MSBV line of multispindle drillheads has been developed to speed up drilling and tapping operations while machining small series of parts. The MSBV drillhead is adjusted and set to a particular pattern in no time, making it justifiable for series as small as 100 pieces.

Prospectus MSBV to the Download on PDF

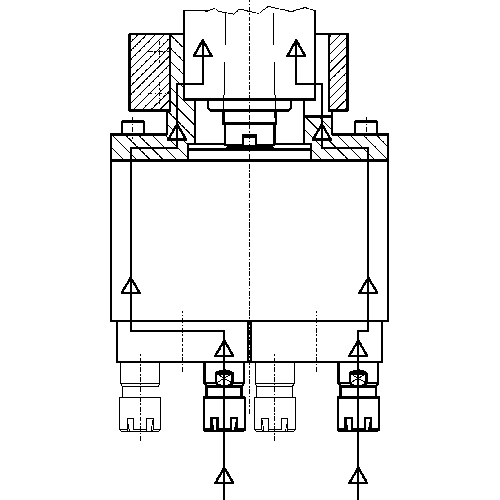

Adaption of BERGER multispindle drillheads

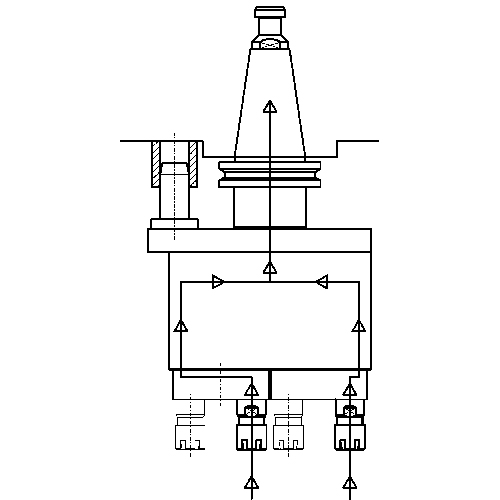

BERGER multispindle drillheads can be mounted to vertually any drilling machine. Two different systems of adaptation are known. The standard adapation uses a non rotating part of the machine (e.g. the quill) to hold on. Most manual drillpresses and drilling units demand this system. On CNC machining centers with automatic tool-change the CNC-adaptaion system is used.

Reduce your machining time and parts-cost, by using BERGER MSBV multispindle drillheads! MBSV multispindle drillheads are available for all common CNC machining centers!

Adaption standard

The above illustration shoes a BERGER mutlispindle drillhead with an adapter for mounting on a non-rotating machine part (e.g. quill, spindle housing, angle iron, etc.). A flange transmits the axial forces from the multispindle drillhead to the machine. The flange is either screwed or clipped to the machine. The driven part supports only the torque required for working.

Question-Form about Adaption standard (PDF)

Fax-Form Adaption standard (PDF)

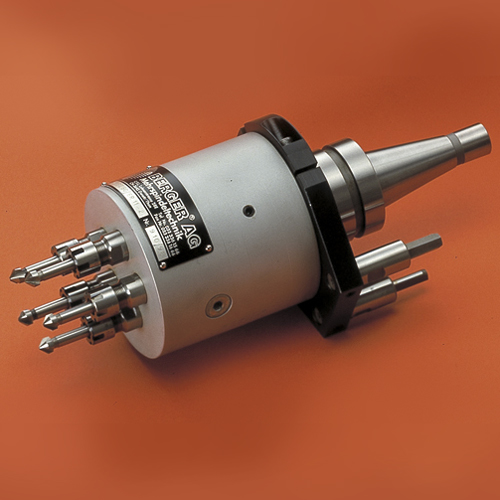

Adaption CNC

The illustration shows a typical adapter for a BERGER multispindle drillhead on a CNC machine. All working forces – the axial forces as well as the required torque – are supportet via a machine-driven part (usually ISO, CAT, BT or HSK Konus). A connection does not support axial forces.

Question-Form about Adaption CNC (PDF)

Fax-Form Adaption CNC (PDF)